arctic seas is an eco-conscious sustainable swim

and beachwear manufacturer

based in Antwerp, Belgium.

Our vision is one that focuses

on high-quality swimwear that

is an expert in the fit of its garments.

arctic seas

We have created garments that will stand the test of time, your experiences & places you will go. We place a heavy emphasis on reducing waste in our production & distribution. This aspect has been pivotal in our inception as it fuels us in the continuous search to be more ecologically friendly. This is our message & the driving force behind our brand as we tell a tale that bridges past, present, & future.

As the earth sees more devastation & threats caused by global warming we must take action to slow the melting of ice & its inhabitants. The polar bear; who depends on the ice for hunting, travelling and shelter, brings balance to the arctic and was the most appropriate choice as our logo. Although these creatures are known to adapt to their environment, at the rate we’re currently destroying their natural habitat, time is not on their side.

Today’s textile industry is built on an outdated model that has adopted a “take-make-dispose” model. A new textile economy is needed in which clothes are designed differently, worn for a longer period of time, recycled, reused as much as possible, contrary to the current fashion industry. We have to strive towards closed circuits in which the materials are used and regenerated again and again and again ..

Each arctic eas garment is made with the highest quality specifications, built to endure elements like saltwater, chlorine and UV-rays. By drawing inspiration from land and sea, we feel a strong connection with fishermen, lifeguards, deep-sea explorers. There are several ways in which we try to make our products more sustainable.

WE USE RECYCLED MATERIALS

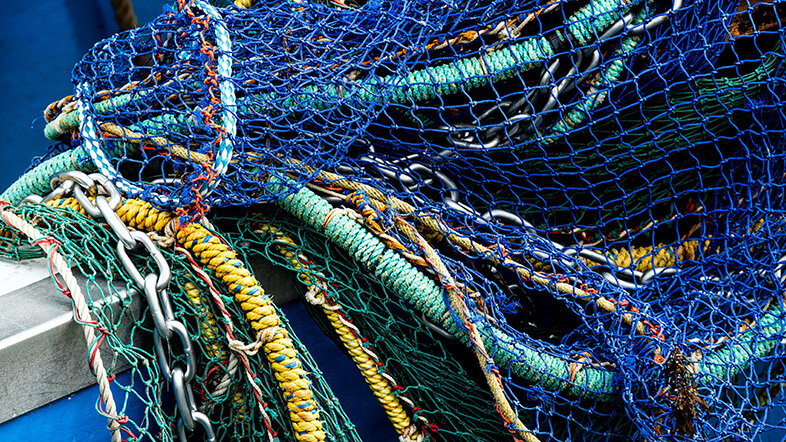

ECONYL®

regenerated nylon made from nylon waste otherwise polluting the earth, like fishing nets, frabric scraps, carpet flooring and industrial plastic.

SEAQUAL

fibers made from 100% post-consumer plastic bottles and plastic waste reclaimed from the Mediterranean Sea, creating yarns that contain about 93 to 95% recycled PET supplemented with 3 to 7% recovered ocean plastics.

NEWLIFE

uses a mechanical process, not a chemical one, to transform bottles

into a polymer. The use of recycled polyester, which requires fewer

processing stages, means less energy is utilized during the

production process, resulting in a considerable reduction

in carbon emissions.

YKK

NATULON®

material recycled zippers: designed for customers who want to increase the recycled content of their products. They are made from recycled materials (such as PET bottles) using the newest in material recycling technologies.

we are in a continuous search to increase

arctic seas’ production process’ eco-friendliness.

FOR THE FINISHES AND TRIMS

We go for recycled materials as much as possible, but the truth is that we haven’t been able to find ecological alternatives for everything ... yet.

WE USE ALTERNATIVE MATERIALS

Alternative materials used include bamboo, banana fiber, linen and fish leather. We actively aim to reduce the amount of water in the production of our fabrics and avoid chemical dyes as much as possible.

NO CENTRAL ARCTIC SEAS OFFICES

All our collaborators work from home and we opt for videoconferencing for most of our meetings.

WE CHOOSE LONG LASTING

HIGH QUALITY MATERIALS AND PARTS

Differing from today’s fashion standards, we opt for producing long-lasting garments with a higher price point over producing high in numbers and low in quality

PRECISION TAILORING

FOR THE PERFECT FIT

Our expert pattern maker (who has worked with Dries Van Noten, Manish Arora and others) sees to it that each garment has the perfect fit, creating clothing less likely to be ‘abandoned’ which in turn means less waste.

PRODUCTION

All production for the EU market

happens in Portugal, near the city of Porto. Nearly all suppliers included in the production of our garments are situated in a 40 km radius of our clothing factory. We only make one (big) sample collection a year,

so transport (of both people and goods)

is cut in half.